Automatic Backwash Filter

Description

Automatic Backwash Filter is a precision filter that directly intercepts impurities by wedge wire screen, removes suspended solids and particulate matter in the water, reduces turbidity and dirt, bacteria, algae, rust, etc. to purify water quality and protect other equipment in the system. Due to the intelligent (PLC, PAC) design, the system can automatically identify the degree of impurity deposition and discharge the sewage.

It overcomes many shortcomings of traditional filtration products, such as small dirt holding capacity, easy to be blocked by dirt, filtering parts need to be removed and clean and unable to monitor the status of the filter. It has the ability to filter the raw water and automatically clean the filter element to discharge sewage.

In addition, the system provides uninterrupted water supply when cleaning and draining the sewage, which can monitor the working status of the filter with a high degree of automation. It covers the requirements of various filtration precisions from 10um to 3000um.

Working Principle

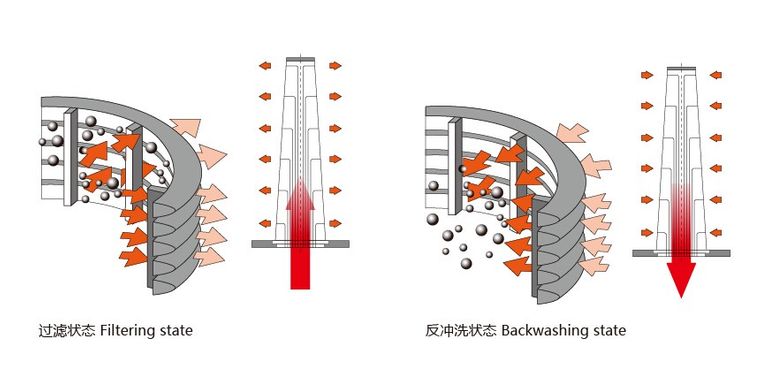

Filtering state:

When the water passes through the filter's coarse mesh, it enters the fine filter chamber, and the impurities gradually accumulate on the fine mesh to form a layer of filter cake.

As a result, a pressure difference is generated between the inside and outside of the fine mesh. When the pressure difference reaches a preset value, the controller makes the hydraulic valve working and water flows out from the hydraulic motor chamber through the hydraulic valve.

Backwashing state:

When the hydraulic valve is opened, the pressure in motor chamber, the collector and the suction nozzle drops to an extremely low point.

This causes a pressure gradient between the fine mesh's outer surface (clear water) and the inner surface (water) of the fine mesh opposite to the suction nozzle. The recoil movement generated by this pressure ladder cleans the filter screen.

When water and impurities pass through the hydraulic motor, the collector will be turned, and the piston in the hydraulic cylinder is driven the collector to move axially.

Finally, when the impurities on the filter screen is backwashed, the pressure difference disappears. The flushing controller closes the hydraulic valve, and the piston returns to its original position. At this time, the entire system returns to the original position and waits for the next cleaning cycle.

Features

- The finest wedge wire screen filter elements with high precision up to 25 um.

- It can easily treat various industrial water, sewage (drainage), surface water, river water/well water and other water sources.

- The operating temperature of the equipment can reach up to 90°C, and the pressure resistance can reach up to 2.5MPa, which can be used in high temperature and high pressure situations.

- High-speed and thorough backwashing can be completed in just 10s. The water consumption of backwashing is only 0.5% of the water output. If combined with air-assisted backwashing, the self-consumption water can be reduced to less than 0.2%

- Flexible use of corner space for installation, equipment with a treatment capacity of 1000m3/h occupies only about 10m2.

- The pressure difference controller has three control functions of pressure difference, time and manual, and can be backwashed by manual button.

- Controlled by a dedicated PLC controller, automatic switching between filtering and backwashing states.

- No special tools, few components and easy to use. Only need regular inspection, almost no daily maintenance.

Application

- Industrial circulating water filtration: used in equipment that has certain requirements for water quality. Such as cooling towers, rolling mills, continuous casting machines, polishing machines, ion exchangers, sprayers, heat exchangers and other water supply and drainage pipelines.

- Raw water treatment: It can filter surface river water, lake water, sea water, reservoir water, well water and ground water to remove sand, bacteria, algae, organic matter and seawater desalination.

- Cooling water treatment: water filtration of cooling towers, supplementary water systems, air-conditioning systems, and DC systems reduces the generation of sediment in the heat exchanger and maintains its cooling effect.

- Metallurgy, petrochemical, food and pharmaceutical industries: Liquid, industrial wastewater, and emulsion regeneration and waste oil filtration treatment, continuous casting water, blast furnace water system.

- Paper making industry: widely used in the filtration of clean water, equipment sealing water, spray water, dry net cleaning water and cooling circulating water to protect nozzles, net cloth, vacuum pumps, etc. in papermaking equipment, and reduce failures caused by clogging and abrasion.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160