Screw Extrusion Solid-liquid Separator

Description

The screw extrusion solid-liquid separator can be widely used in the separation and dehydration of solid-liquid separation and dehydration of chicken manure, pig manure, cow manure, sheep manure, rabbit manure and other livestock and poultry manure sewage, as well as wood chips, pulp, medicine residue and other solid-liquid separators in livestock farms. The components of the extrusion solid-liquid separator are mainly composed of stainless steel main body, feed pump, water pipe, control cabinet, mixer, etc.

Working Principle

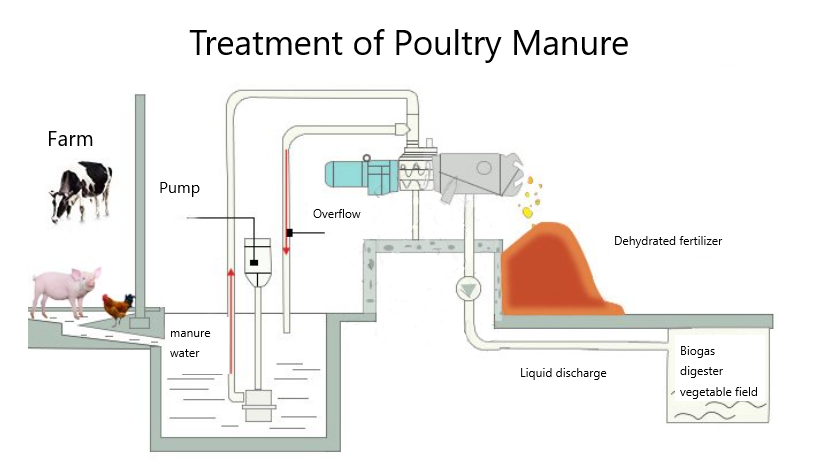

First, the manure water is pumped into the screw extrusion solid-liquid separator by the matching non-blocking submerged pump, and then the manure water is gradually pushed to the front of the machine by the auger, and the pressure of the front edge of the machine is continuously increased to force the material to enter The water squeezed out of the mesh screen under the action of the side pressure belt filter and flows out of the drain pipe. The work of the screw extrusion solid-liquid separator is carried out continuously, the manure water is continuously lifted into the screw extrusion solid-liquid separator, and the pressure of the leading edge increases continuously. The material port is opened and extruded from the extrusion port to achieve the purpose of extruding and discharging. In order to control the discharge speed and water content, the counterweight block under the main machine can be adjusted to achieve a satisfactory and appropriate discharge state. If too much manure is pumped in, it will be discharged to the original manure tank through the overflow pipe, and the cow manure wastewater separated by screw extrusion and filtration can be directly sent to the biogas tank for fermentation of biogas or discharged to its wastewater sedimentation tank, etc.

Features

- The screw extrusion solid-liquid separator has small volume, low speed, simple operation, convenient installation and maintenance, low cost, high efficiency, fast investment recovery, and no need to add any flocculant.

- High level of automation, easy maintenance, large daily processing capacity, small footprint, fully enclosed, environmentally friendly and hygienic, low power consumption, suitable for continuous operation. Its key components are made of stainless steel, the weight of the whole machine is nearly half a ton and the external dimensions are small.

- Excellent dewatering effect on pulp from paper mills and distiller's grains from wineries, and low moisture content in discharge.

- The separated solid part is dry and has no odor. It is a good farmland fertilizer. It is convenient for transportation and storage. pollution problem. After separation, the moisture content of the liquid part is about 60%, and it is not easy to produce crusting and precipitation during the storage process. The separated liquid ammonia and phosphorus content is small, which can be diluted for irrigation water or water and fertilizer.

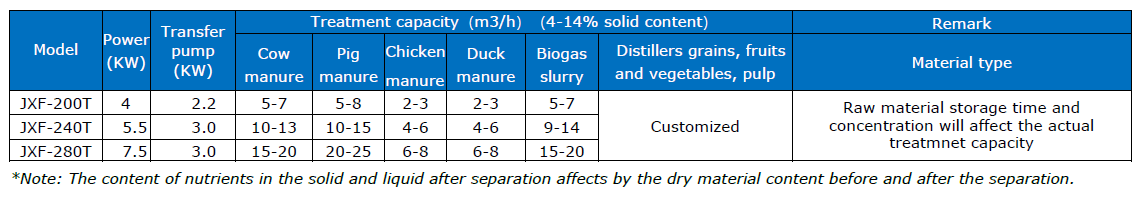

Model

The application of livestock and poultry manure after treatment:

- The dry cow dung separated by dehydration is almost odorless, and the viscosity is small, which can be used directly as fertilizer, or used as cow bedding material.

- The dehydrated and separated dry cow dung is mixed with straw chaff and fully stirred, added with bacteria for fermentation, and granulated to make compound organic fertilizer.

- At the same time, it can be made into pellet feed, which is a good feed for fish.

- It is used for fertilization of flowers/special economic crops, which can transform the organic matter of the soil.

- Additional economic benefits can be obtained by selling organic fertilizers.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160