Candle Filter

Description

Candle filter is a more advanced, safe, efficient, pollution-free new filtration mode, candle filter has high efficiency and energy saving, closed and high precision, easy maintenance, safe and reliable, high degree of automation and other characteristics, can be widely used in petroleum, plastics, electroplating, chemical, ceramics, pharmaceutical, sugar and other industries of solid-liquid separation filtration.

Candle filtration has gradually replaced the filter press and bag filtration as the mainstream filtration method, in which the repeated use of the filter medium has saved a lot of filter consumables. The cylinder is tightly sealed to ensure that the production process has no leakage. The microcomputer automation control is not only a good maintenance of the continuity of enterprise production, but also greatly reduces the risk of production accidents while improving production efficiency and saving labor.

Working Principle

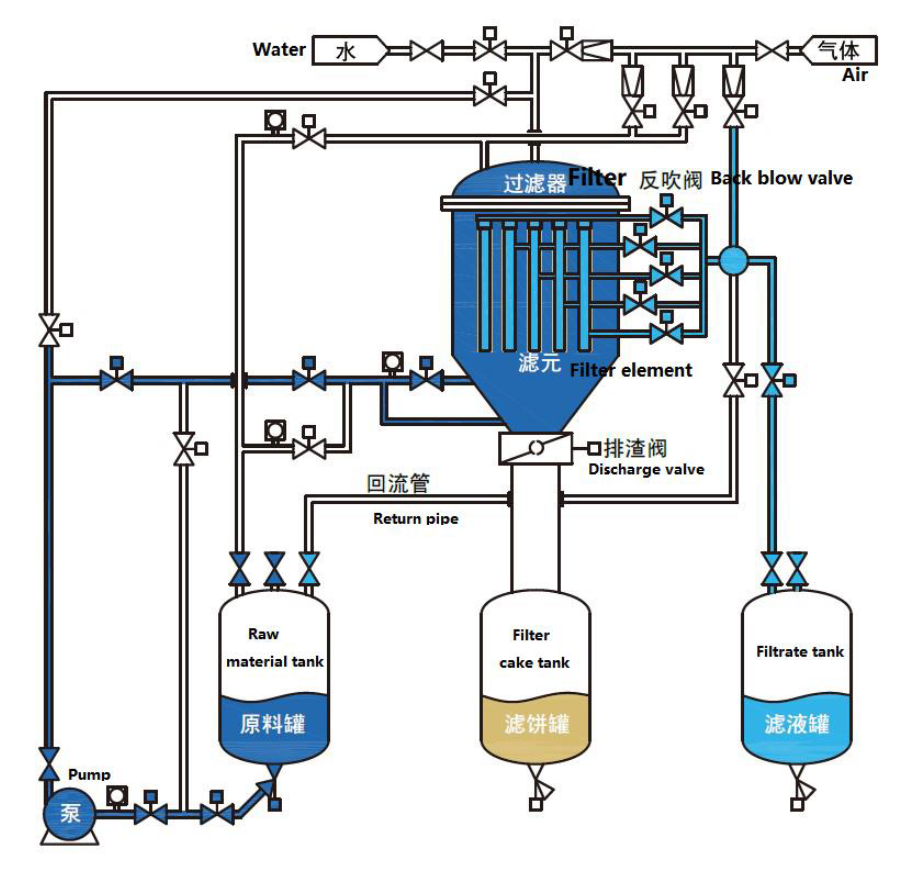

When the liquid passes through the filter, the particle impurities in it are blocked on the outer surface of the filter element, accumulating to form a filter cake, so that the pressure difference between the inlet and outlet of the filter gradually becomes larger, when the pressure difference reaches a certain default value (150KPa), it indicates that the filter cake reaches a certain thickness, at this time the filterable flow of the filter element is getting smaller and smaller, the controller starts the backwashing action.

The liquid flows backwards from the inside of the filter element to the outside, taking away the impurities on the surface, using the reverse flow of the filter liquid to flush the filter cake on the outer surface of the filter element, when backwashing, The controller switches a set of valves of the filter to be backwashed, that is, close its inlet valve, and then open the sewage valve, part of the liquid of the filtration liquid reverse flow backwash the filter, quickly remove the filter cake on the surface of the filter element, discharge the residual liquid into the sewage collection pipeline, and then close the sewage valve, open the inlet valve, and return to the normal filtration state.

Features

- Completely enclosed high safety system, no rotating mechanical moving parts (except pumps and valves).

- Fully automatic filtration.

- Simple and modular filter elements.

- Movability and flexibility of the design to meet the production cycle short and frequent batch production requirements.

- Achieve sterile filter cake in the form of dry slag, slurry and re-beating slag discharged into sterile containers.

- Patented spray washing system can save the consumption of washing liquid to a greater extent.

- Patented volume filtration enables almost 100% recovery of solids and liquids, thus ensuring the integrity of batch filtration.

- Candle filter can easily achieve CIP cleaning, all parts can be removed for inspection and inspection.

- Filter cake washing, drying and unloading cake is simple.

- Step-by-step SIP sterilization with steam or chemical methods.

- Filter cloth and product properties are completely matched.

- Can be used for the production of free particle injection.

- All sanitary fittings are sealed with O-rings in accordance with GMP flange requirements.

- Activated carbon filters are equipped with aseptic pumps and instruments.

Application

Applicable industries: petrochemical, beverage, fine chemicals, grease, water treatment, titanium dioxide, electricity, polysilicon, etc.; Applicable fluids: resin, regenerative wax, cutting oil, fuel oil, lubricating oil, machine cooling oil, transformer oil, bone glue, gelatin, citric acid, syrup, beer, epoxy resin, polyol, etc.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160