Channel Drum Screen

Description

Channel Drum Screen can extract the finer floating matter, suspended matter and sediment in the sewage, and then discharged after conveyed and pressed. The filter residue is squeezed and dehydrated during the transportation process, and the solid content can reach 35%-45%. The dry residue is small in size and has little pollution, and it is easy to transport and process.

Working Principle

The equipment is installed in the water channel at 35 ° to the horizontal plane. The sewage flows into the channel drum screen from the end of the screen. It traps suspended matter and floating objects in the water in the grille. The sewage flows out from the cracks of the screen. Rotating slowly, there are nylon brushes and flushing water nozzles above the screen. The grid slag is removed from the grid gap, and at the same time it is conveyed by the screw and squeezed for dehydration, and finally through the upper discharge port. The material falls into the trash bin or the conveyor and transported out.

Features

- High quality and reliability at low cost.

- Reduced disposal costs because of the screenings press.

- High solids capture.

- Easily installed onto an existing or new treatment works.

- Non-clogging even with fibrous materials.

- Protection of downstream plant and drains.

- Improved Health & Safety with optional continuous bagging.

- Enclosed drum screen to prevent wastewater splash.

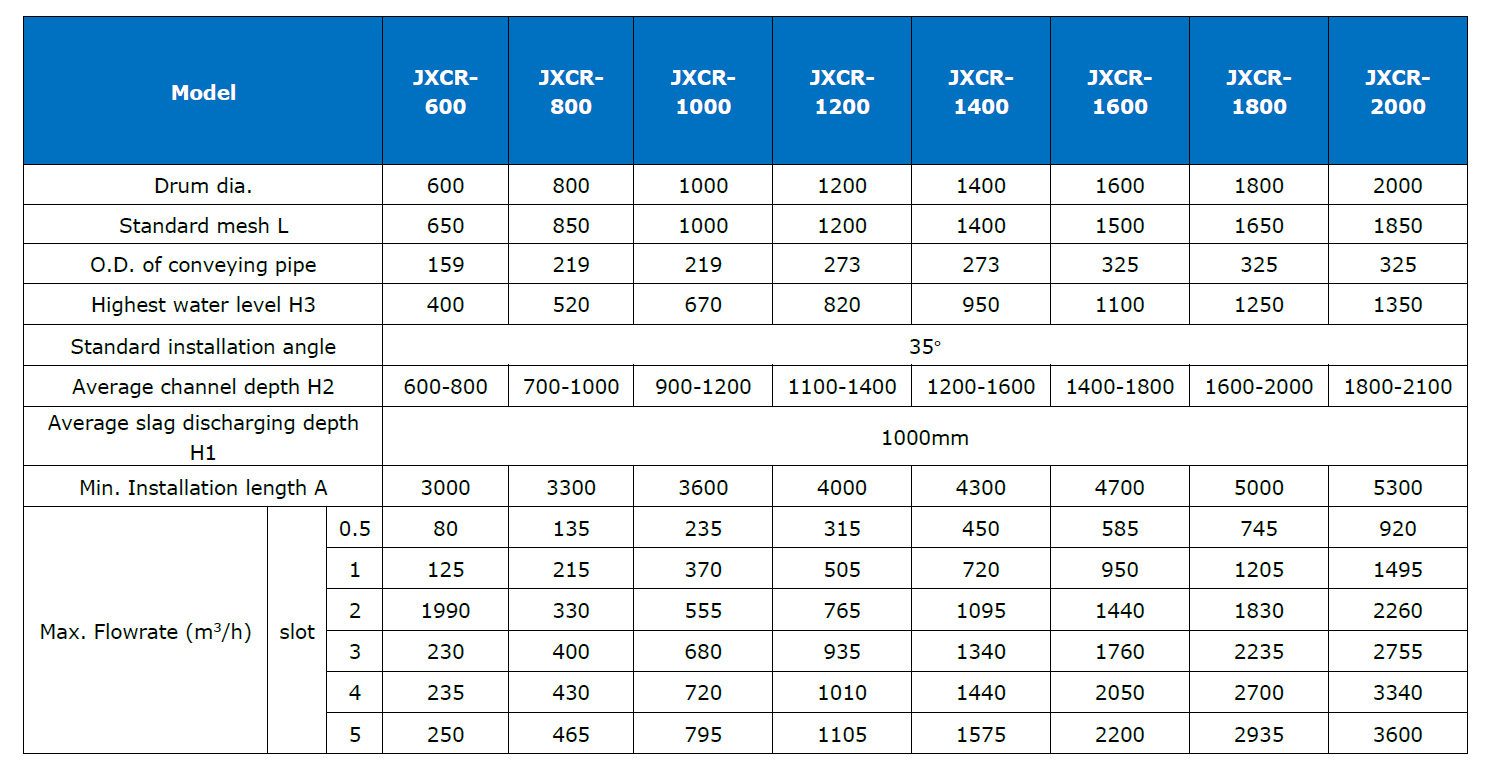

Model Selection

Application

- Process liquor or fluid screening

- Municipal wastewater treatment works

- Industrial effluent discharges

- MBR Membrane pre-screening

- Commercial outlet discharges

- Storm flows

- Sea outfall discharges

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160