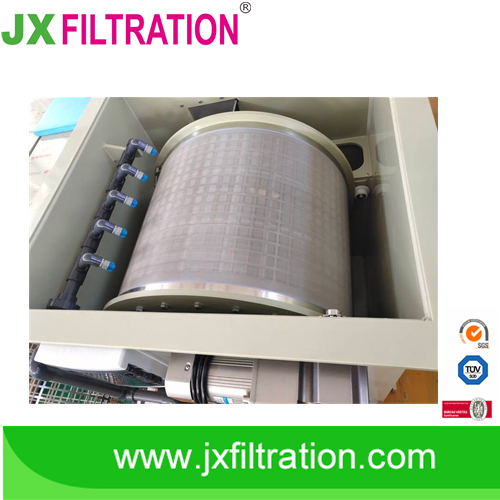

Rotary Drum Filter for Fish Farm

Description

Rotary Drum Filter for Fish Farm is designed with German technology and double braided mesh sieves. The water passes from the inside of the drum through the mesh sieve into the clean water room. During that, the suspended solids larger than the size of the mesh holes are kept on the surface of the mesh sieve and then washed into the collecting slot from where they flow out of the system. The mesh size is from 30μm to 100μm.

The Rotary Drum Filter for Fish Farm housing is made by PP or 316L stainless steel, which is widely used in freshwater and marine aquaculture treatment. It can separate suspended solids greater than 90% in water (such as excrement, feces, cyanobacteria and other organic debris, etc.). This mesh rinsing system in delousing salmon rotary drum screen is activated automatically by water level control or timer. During rinsing the drum will start rotating simultaneously.

Basic Structure & Working Principle

- It uses a rotating stainless steel drum screen to achieve filtration. There is a dense 316L stainless steel screen on the outside of the drum. The drum screen can be driven by a motor through gears.

- On the outside of the filter, there is a pressurized water pump composed of a plastic pump casing. The pressurized water pump is connected to a row of plastic nozzles.

- Inside the box, there are two water level controllers, which can transmit signals to the control electric box according to the water level change.

- There is a large-diameter water inlet, a small-diameter drain, and a sewage pipe on the box body. The drainage adopts the rear-mounted water pump.

Features

- Adopts SS316L drum screen: can withstand the liquid with PH over 11 for a long time without rust. And a special weaving method is used to increase the strength of the screen.

- The driving mode of the drum is changed from the central shaft drive to the external gear drive. The probability of failure is greatly reduced and the screen can be washed more cleanly.

- The drum screen adopts the form of outer flange to make it is easier to repair, replace or clean.

- The water level controller is a non-contact solenoid type to prevent seawater corrosion or other matters from entering.

- The outlet pipe is connected to the water pump which can make the rotary drum filter has a larger effective filtering area and reduce the frequency of backwashing.

- There are many options for backwash control, such as water level control, timing control, time interval control, and manual control.

Technical Data

- Shell material: PP or SS304,316

- Body type: Box

- Rotary drum screen: SS316L

- Drive mode: Gear box

- Filter precision: 30-100um

- Cleaning system: automatic backwashing

- Treatment capacity: 30-500m3/h

- Inlet/outlet size: can be customized per requirements.

- Application: RAS project, aquaculture water treatment.

*Other associated equipment is available: protein skimmer, bio filter, UV sterillizer etc.

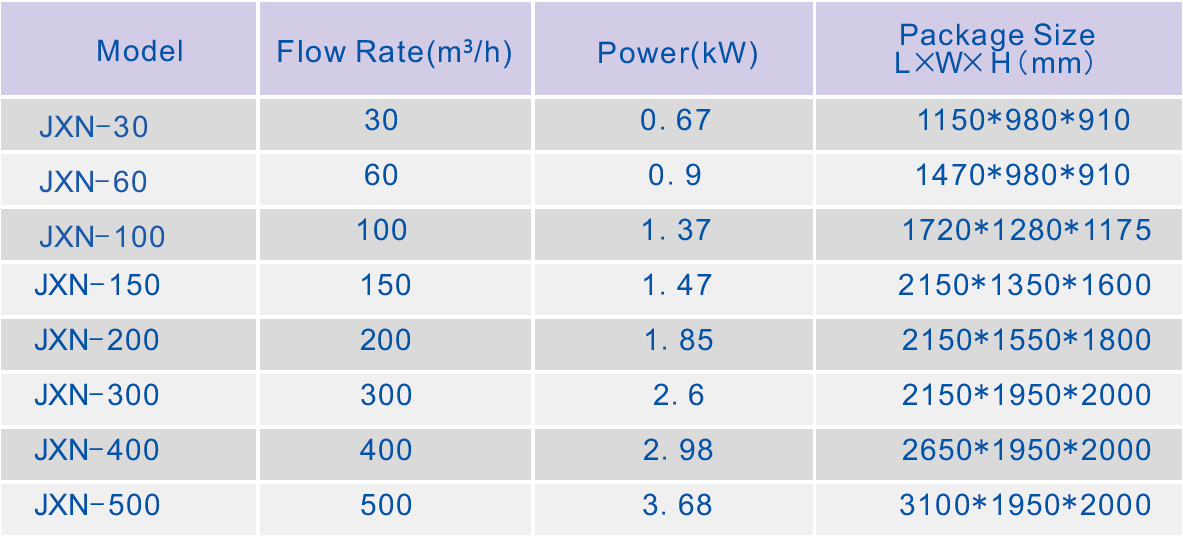

Model Selection

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160