Sludge Screw Press

Description

The Sludge Screw Press adopts a multi-overlap spiral filter press method, which has the features of self-cleaning filter slits, no block, saves water and electricity and durable. It creates a direct dewatering of low-concentration sludge (2000mg/L~), and can realize 24-hour continuous unmanned operation, while greatly reducing the cost of design, construction, operation and maintenance management.

Working Principle

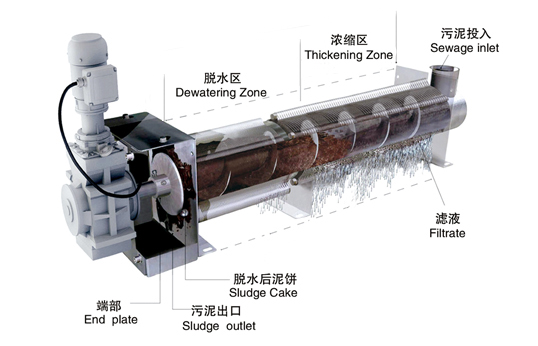

The working principle of Sludge Screw Press is divided into three parts: concentration, dehydration, and self-cleaning.

Concentration

When the screw pushing shaft rotates, the multiple fixed and portable plate arranged on the periphery of the pushing shaft move relatively. Under the action of gravity, water is filtered out from the gaps of the relatively moving plate to achieve rapid concentration.

Dehydration

The concentrated sludge moves forward with the rotation of the screw shaft. Along the direction of the sludge cake outlet, the pitch of the screw shaft gradually decreases, the gap between the plates gradually decreases, and the volume of the spiral cavity keeps shrinking. Under the action of the back pressure plate at the outlet, the internal pressure gradually increases. Under the continuous operation of the screw drive shaft, the water in the sludge is squeezed and discharged, and the solid content of the filter cake continues to increase, and finally the continuous dewatering of the sludge is realized.

Self-cleaning

The rotation of the screw shaft pushes the portable plate to continuously rotate. The equipment relies on the movement between the fixed plate and portable plate to achieve a continuous self-cleaning process, thereby cleverly avoiding the common blocking problem of traditional dehydrators.

Features

- Small and compact design, dewatering machine contains an electronic control cabinet, metering tank, flocculation mixing tank and dewatering machine body. Small footprint and weight for easy maintenance and replacement.

- Suitable for dehydration of high and low concentrations of sludge. When low concentration (2000mg/L)sludge is dehydrated. There is no need to build a concentration pool, storage tank, reduce construction costs, reduce phosphorus release and anaerobic odor.

- Not easy to clog with self-cleaning function. No cleaning is required to prevent blockage of the filter, reduce flushing water consumption, reduce the burden of internal circulation. Good at dehydration of oily sludge.

- Simple operation, through the electronic control cabinet, and dosing device, sludge screw pump, drug pump, etc. to carry out a continuous 24 hours.

- Low-speed operation, spiral shaft speed of about 2-3 rpm, low power consumption. Fewer faults, low noise vibration, safe operation.

- Daily maintenance time is short and maintenance work is simple. The durable, almost all of the body is made of stainless steel to maximize service life. The replacement parts are only spiral shafts and portable plates.

Model Selection

Application

Municipal sewage, domestic sewage, food, beverages, chemicals, leather, welding materials, paper making, printing and dyeing, pharmaceuticals, electroplating, oil fields, coal mines, wine making, livestock breeding, kitchen wastewater, water plants, power plants, steel plants.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160